Pneumatic solutions for low-temperature operation are indispensable in numerous key industries, including medical technology, research, food processing and industrial automation.

The reliable functioning of mechanical components at temperatures as low as –40°C places high demands on materials and design.

This underscores the importance of specialized pneumatic components that are designed and tested for these specific applications - ensuring maximum operational reliability and efficiency even under extreme conditions.

Choosing the right sealing material is crucial for the reliable operation of pneumatic components at low temperatures. Only specially formulated elastomers guarantee a lasting seal and thus a long service life for the components - even at temperatures as low as –40°C.

A major problem is that many standard elastomers become brittle in cold conditions or lose their sealing function.

In addition, suitable materials for low-temperature applications are often not available as standard gaskets. In such cases, it is necessary to manufacture custom gaskets, including the production of tools.

Our solution: We select the appropriate sealing material specifically according to the requirements and, if necessary, manufacture the tools required for the production of customized gaskets.

This ensures that every component functions reliably, even under extreme conditions.

Elastomers suitable for –40°C °C

| Elastomer | Temperature range (approx.) | Characteristics | Typical applications |

| NBR (nitrile rubber, low-temp type) | –40 °C bis +100 °C | Good oil and fuel resistance; special formulations required for low temperatures | Pneumatic gaskets, hydraulic systems |

| EPDM (ethylene propylene diene rubber) | –45 °C bis +130 °C | Excellent resistance to ozone, water, and weathering | Gaskets, hoses, brake systems |

| VMQ (silicone rubber) | –60 °C bis +200 °C | Excellent low-temperature flexibility, resistant to aging and UV radiation | Medicine, food technology, pneumatics |

| FKM (Viton® / fluorinated rubber – low-temp type) | –40 °C bis +200 °C | Very good chemical and thermal resistance, low gas permeability | Chemical plants, automotive engineering |

| PU (polyurethane – thermoplastic) | –40 °C bis +80 °C | Highly resilient to mechanical stress, abrasion-resistant | Pneumatic gaskets, hose coverings |

The choice of the appropriate elastomer always depends on the specific application. In addition to the temperature range, numerous other factors play a decisive role:

- Operating pressure: Different pressure resistances are required depending on the application.

- Switching frequency: Elastomers must be designed for a high number of switching cycles depending on the application.

- Medium purity: The chemical composition and purity of the media (e.g., compressed air, gases, liquids) influences the choice of material.

- Resistance to external influences: These include:

- UV and ozone exposure

- Moisture or aggressive media

- Mechanical stress and abrasion

- Compatibility with cleaning processes, e.g., in sterile or food technology applications

Only by taking a holistic view of all operating conditions can a suitable material be selected that remains both durable and functionally reliable.

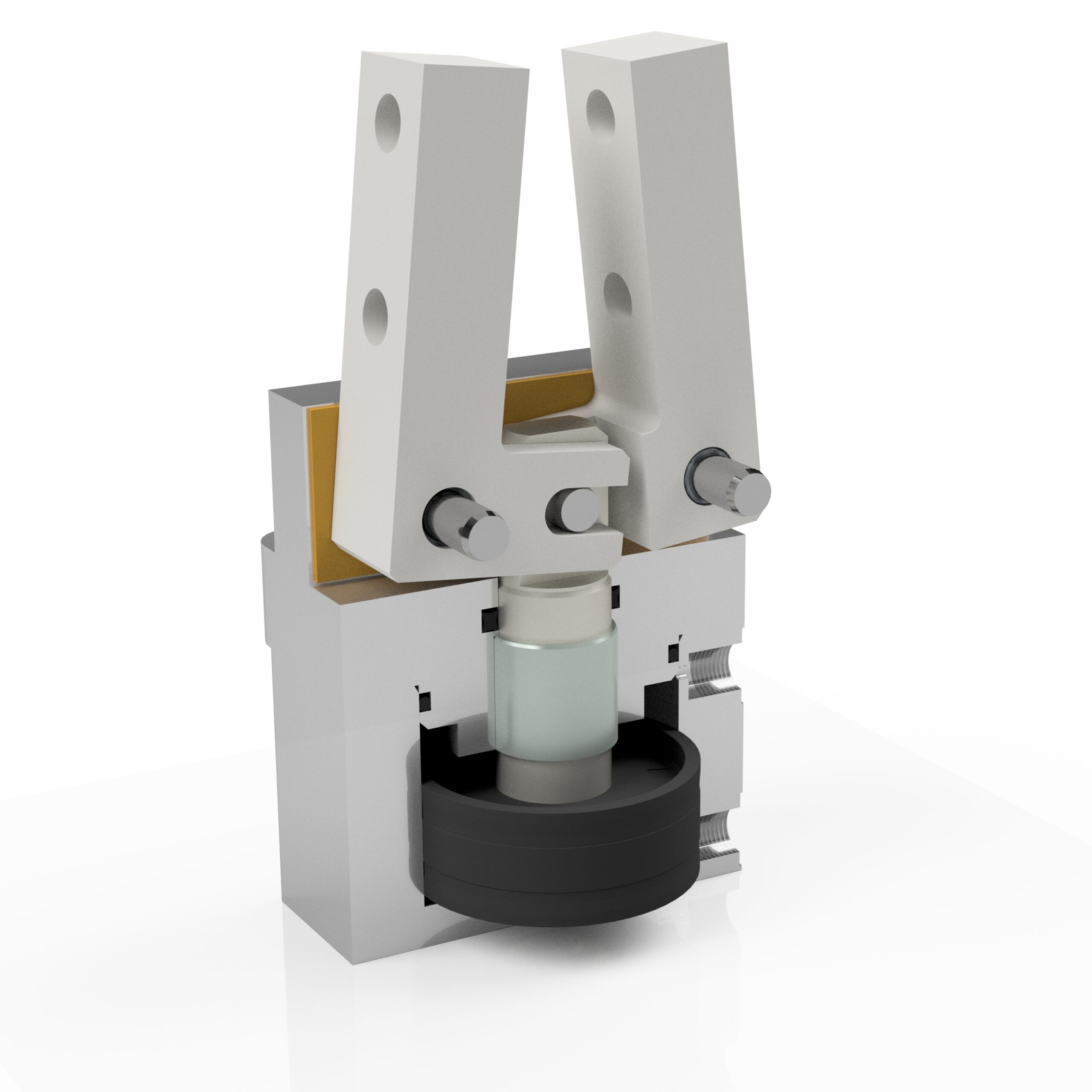

At SFS-Fluidsysteme GmbH, we develop customized pneumatic solutions for reliable use in low-temperature ranges down to -40°C. Each component is specifically designed to meet the special requirements, constructed and extensively tested during development.

Our portfolio includes all core components of pneumatics - tailored to your requirements:

- Pneumatic cylinders with piston diameters from 4 mm to 125 mm

- Solenoid valves

- Spool valves

- Stop valves

- Check valves

- Pressure regulators