A pressure regulator with secondary venting regulates the pressure by releasing excess air or gas on the outlet side when the pressure exceeds the set value or when the outlet pressure needs to be reduced without withdrawing air. This is done through a small opening in the spring cover, through which the medium can escape into the open air.

If a pressure regulator does not have secondary venting, it can not reduce the pressure on its own if it rises above the set target pressure at the outlet.

So why are there still pressure regulators without secondary venting, and what are they used for?

As mentioned, pressure regulators without secondary venting can not reduce the excess pressure on the outlet side. If the outlet pressure rises, it cannot be actively reduced but must be lowered in another way.

Pressure regulators without secondary venting are often used in applications where a pressure increase on the outlet side is unlikely or where pressure relief is ensured by other means (e.g., controlled leakage or a check valve).

In addition, pressure regulators without secondary venting are frequently used for liquids, especially water, to prevent escaping media from entering the environment. Secondary venting would allow liquid to escape in the event of a defect or overpressure in the regulator, which is undesirable and could cause damage.

The same applies to aggressive or toxic media. As the escaping media are toxic substances and must therefore not be allowed to escape into the environment. When using pressure regulators with aggressive or toxic media, it is important that the escaping medium is discharged in a controlled manner to avoid health hazards or environmental damage.

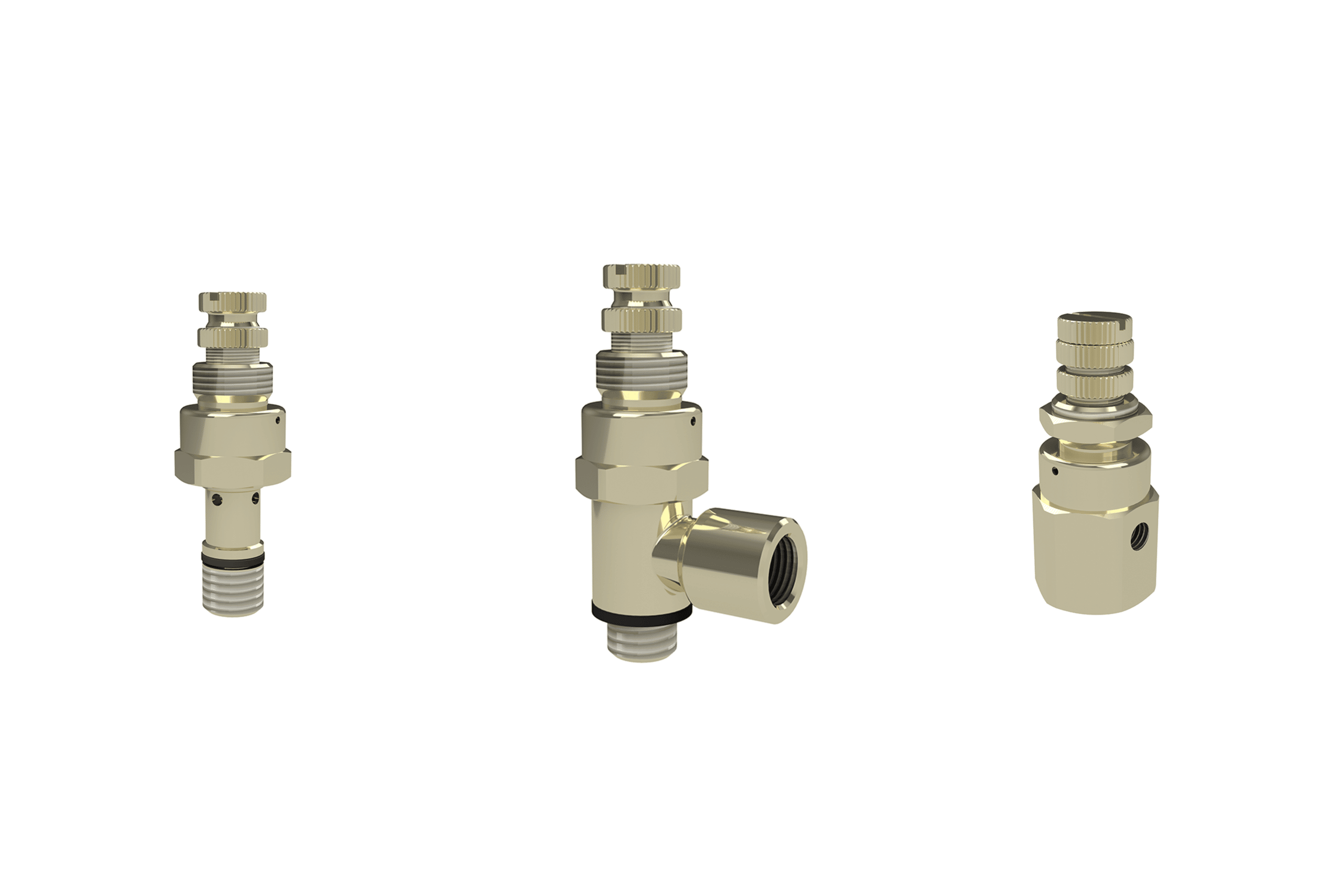

At SFS-Fluidsysteme GmbH, we offer pressure regulators with or without secondary venting and build customized solutions that are perfectly suited to your application.