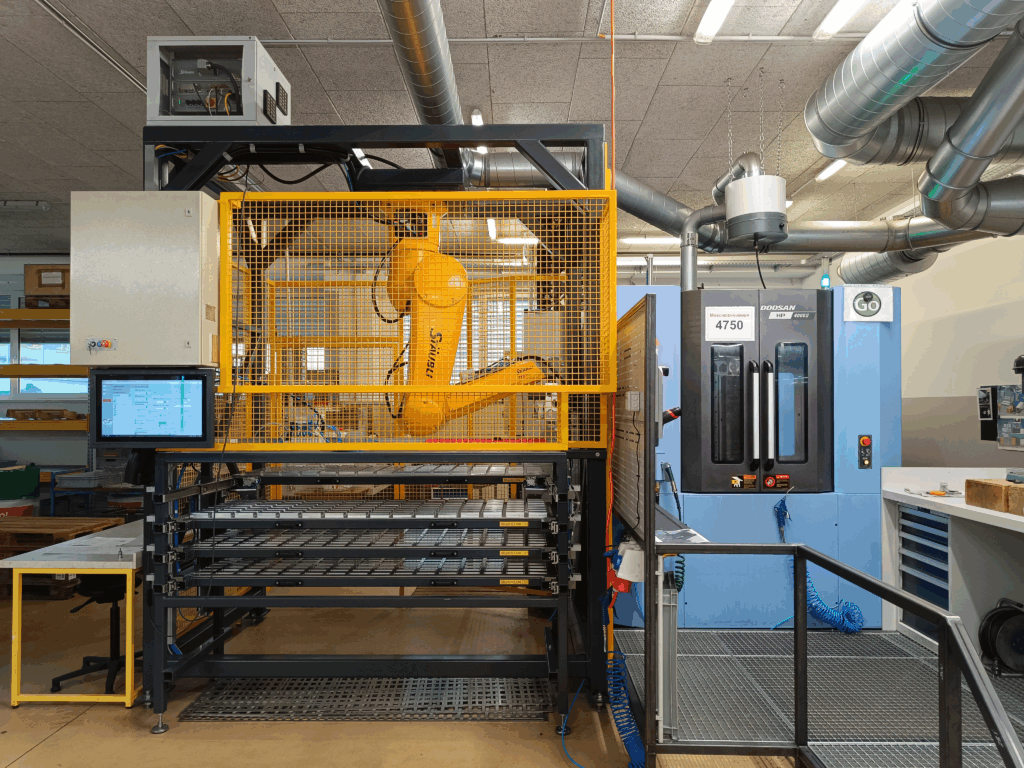

To increase productivity, improve process reliability, and reduce manufacturing costs, an automation solution for parts feeding was implemented on a CNC milling machine. The core component is an industrial robot that automatically feeds raw parts and removes finished parts. This reduces manual setup and handling times while enabling stable and cost-efficient production in multi-shift operation.

1. Initial Situation

- Before automation, parts were manually fed by operators, allowing them to actively manage the production process.

- As a result, the milling machine could only operate when an operator was present.

- Especially for medium to high quantities, there was potential to further optimize processes to maintain competitiveness in international markets.

- At the same time, the new solution was designed to be flexible, enabling seamless switching between manual and automatic parts feeding

2. Automation Solution

2.1 Hardware

- Industrial Robot:6-axis articulated robot (payload 40 kg, reach approx. 2000 mm)

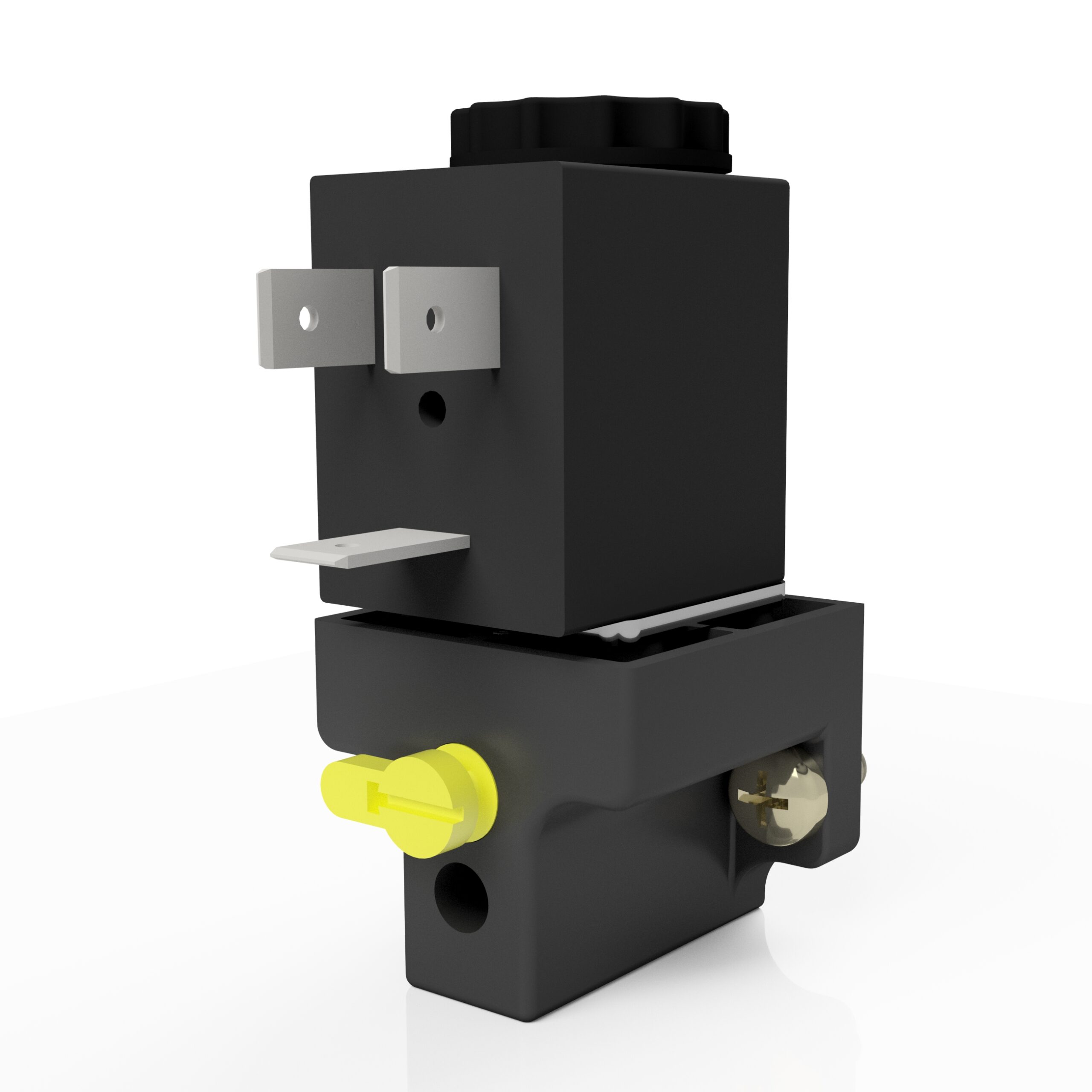

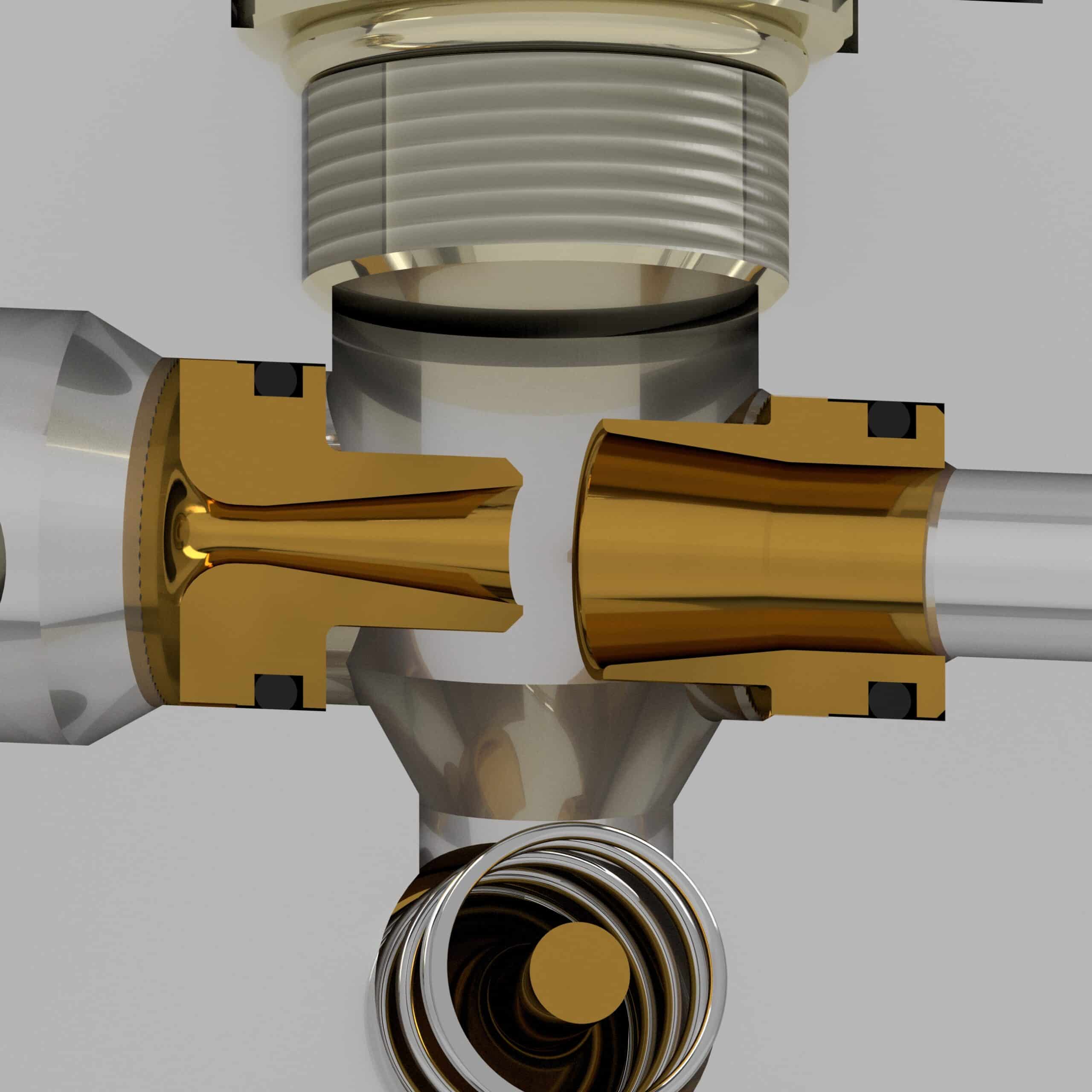

- Gripper:Pneumatic gripper for raw and finished parts

- Peripheral Equipment:Drawer magazine with zero-point clamping system

- Milling Machine:CNC machining center with automatic door opener and standardized robot interface

2.2 Security concept

- Protective fence

- Safety doors with interlock

- Safe-zone monitoring of robot movements

3. Results & Benefits

- Increased Productivity:Instead of the previous single-shift operation, near-continuous production (24/7) is now possible. This significantly reduces downtime and at least doubles machine output.

- Process Reliability:Reproducible handling ensures consistent quality.

- Employee Relief:Ergonomically demanding tasks are largely eliminated.

- Flexibility:Different workpiece types can be handled through gripper changes and adjustable drawer magazines.

4. Conclusion

The automated parts feeding by an industrial robot represents an important step for our company in increasing efficiency and securing competitiveness. In addition to relieving the operators, the solution enables much better utilization of the milling machine and ensures consistent quality.

Depending on the workpiece, we now achieve up to four times the previous parts output compared to the manual single-shift operation. This provides a future-proof solution, keeping us competitive even in highly price-sensitive markets, such as the automotive industry.