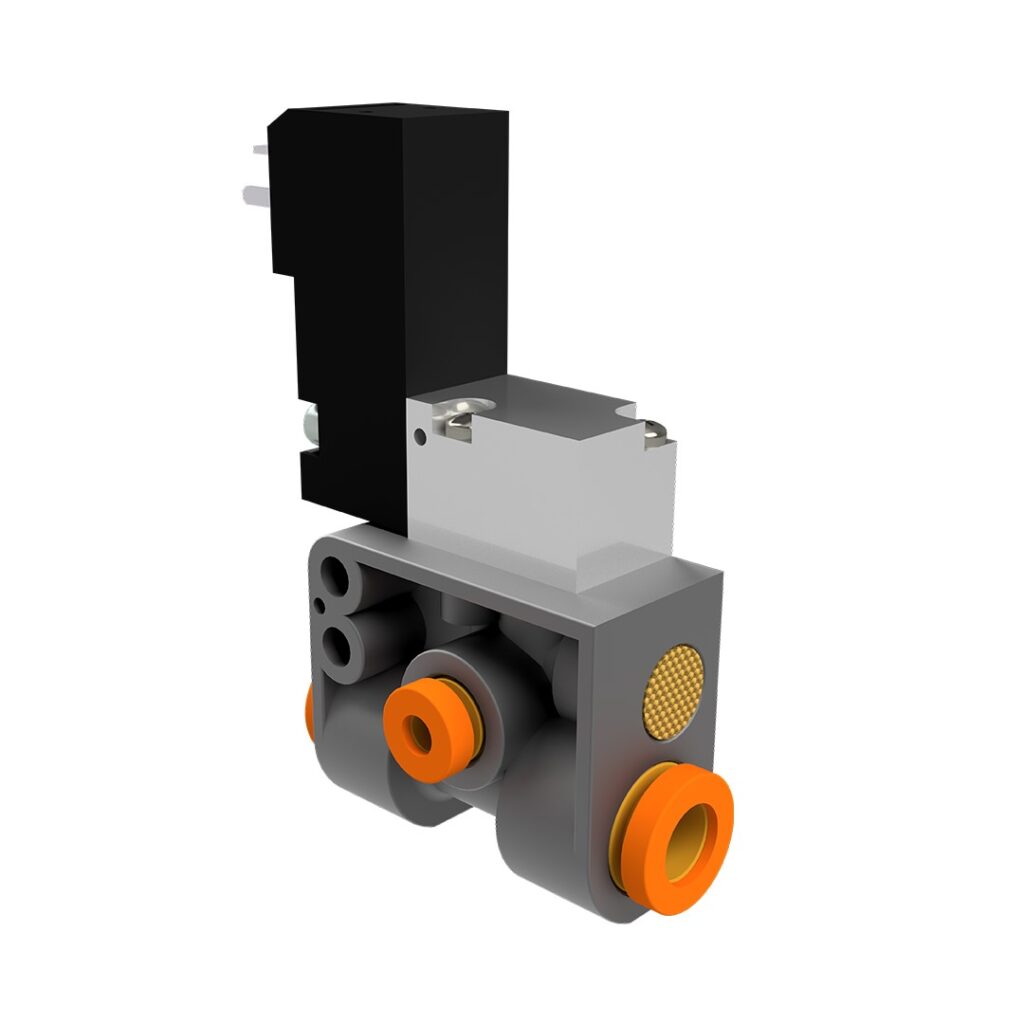

These small, compact 3/2-way valves with integrated quick exhaust are mainly used for highly automated intralogistics solutions to efficiently store goods and products and then transport them automatically and as quickly as possible to a desired destination or packaging station. They are used in consumer goods, industry, the food sector and textile industry. Within the logistics solution the valve has the task of maintaining the direction of the goods during retrieval or diverting them in the other direction by means of a switch.

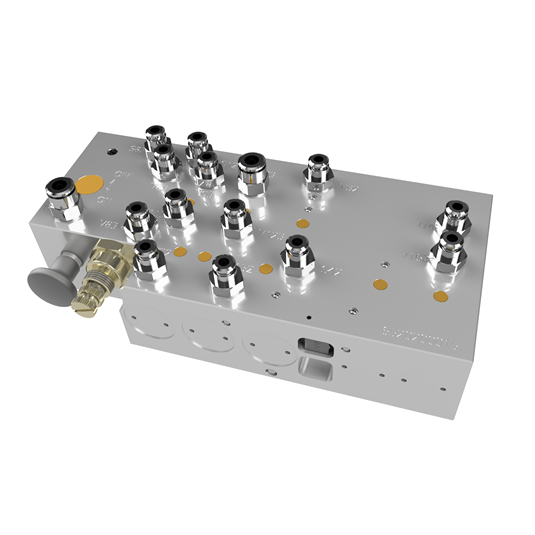

As the name suggests, this valve consists of a 3/2-way valve with an integrated quick exhaust. The valve has an 8 mm pressure connection that passes through the valve and supplies the next valve and all other valves with compressed air. The 4 mm pressure outlet is automatically pressurized when the valve is not electrically controlled and thus has a NO (normally open) function.

If the 3/2-way 10 mm valve is electrically actuated, the outlet becomes unpressurized and the compressed air in the line is vented to the environment in the shortest possible time via the integrated quick exhaust. By applying compressed air or quickly venting the compressed air, the switch is directed in the correct direction for product transport. If necessary, or in the event of a power failure, the valve can also be operated manually.

At SFS-Fluidsysteme GmbH, this control valve is available with integrated strands or with a plug connection according to DIN and is manufactured from injection-molded plastic parts for an optimal price-performance ratio.